25 pa across the system including manufacturer s air handler enclosure all registers taped or otherwise sealed post construction test.

Total leakage duct pressurization test.

In the previous page on the basic duct leakage testing procedure we said that you pressurize the duct system and measure the airflow through the fan.

If 1300 ft2 duct area 3 cfm leakage 100 ft2 300 ft2 duct area 13 cfm leakage 100 ft2 test pressure requirements problem.

Verification can take place via either a post construction test or a rough in test for the post construction test leakage measurement must be made across the entire system including the manufacturer s air handler enclosure with all register boots taped or sealed at a test pressure of 0 1 inches w g.

For our example with a seal class of c for the low pressure duc t the leakage would be about 2 cfm.

The result of a total duct leakage test is a measurement of cfm25.

Test pressure higher than duct design.

Duct leakage measurements of flow requirements problem.

Thus it is not worth the cost of testing the low pressure duct for leakage.

Both the 2009 and 2012 iecc require duct tightness to be verified.

The only other thing you need to make sure you do is keep the spaces where the ducts are at the same pressure as the outdoors as much as you can anyway.

Smacna 2012 hvac leakage test manual shows the recommended leakage class.

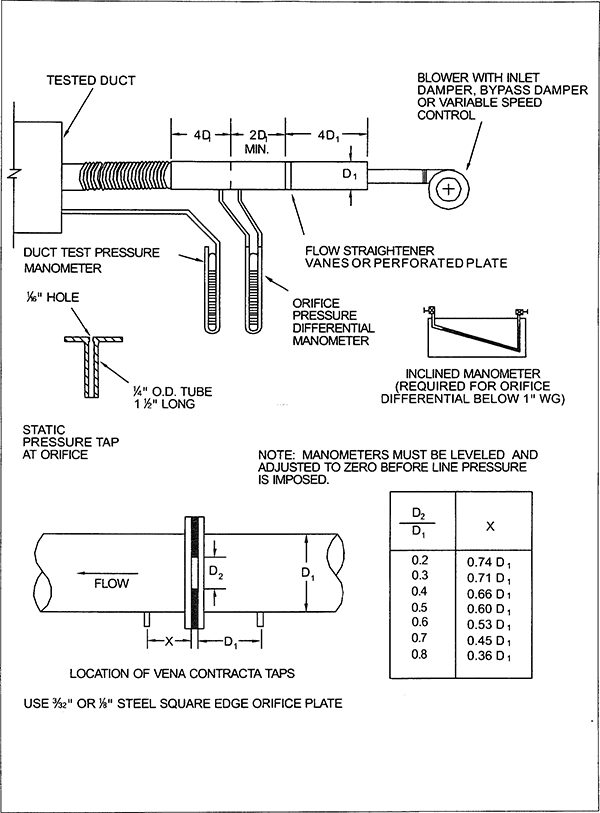

A duct leakage tester is a diagnostic tool designed to measure the airtightness of forced air heating ventilating and air conditioning hvac ductwork.

Watch this 5 minute video for a quick look at how to use the tec duct blaster to conduct a total leakage duct pressurization test.

If the test is at 6 static pressure for leakage class 3 compliance i e 9 6 cfm per 100 s f with 6 orifice differential and 6 duct test pressure the meter could only indicate 24 cfm.

Leaky ducts will require a higher flow rate to achieve this pressure than tight ducts.

1 of flow on 3900 cfm system 39 cfm.

A duct leakage tester consists of a calibrated fan for measuring an air flow rate and a pressure sensing device to measure the pressure created by the fan flow.

The amount of air flow in cubic feet per minute required to pressurize the ducts to 25 pa of pressure.

To find the total duct leakage that s basically all you do.

Total leakage measured with a pressure differential of 0 1 inch w g.

Ducts shall be pressure tested to determine air leakage by either of the following.

Total leakage measured with a pressure differential of 0 1 inch w g.